Lean RFS: It's systemic change and lean production, baked into one

Lean Repetitive Flexible Supply is one of just a handful of time-based approaches to industrial settings. It's perfect if you are looking or high performance & flow, and if you want to get there fast

When, in the 1940s, Taiichi Ohno set out to reshape Toyota’s production into to what is now commonly referred to as TPS or Lean Manufacturing, he did not start off with the now-famous “single-piece-flow.” Instead, he and his teams had to discover how to break large production batches down to ever-smaller batches, by reducing changeover times, testing different takes on shop floor arrangement, and reorganizing the work. It took Ohno and Toyota a full three decades to arrive at single-piece flow (or: batches of one) and to integrate most of their process steps into the flow, including much of their suppliers’ processes.

In some industries, however, achieving batches of one like Toyota will forever remain illusive: We are talking about high-volume production, which is common in the so-called Fast-Moving Consumer Goods and process industries. Companies here have long struggled to identify suitable lean approaches that are capable of achieving flow, and that are sufficiently systemic to amount to more than dabbling. It is here where the brilliant Lean RFS concept comes into play.

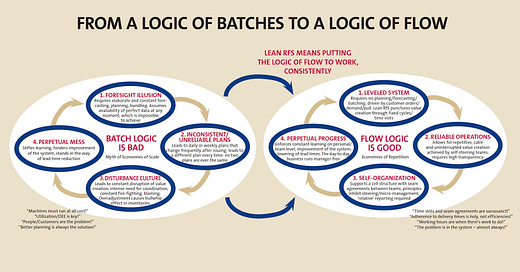

In the 1990s, Ian Glenday discovered a take on organizing high-volume production in a way that resembled Toyota’s early efforts to get to small(er) batches, and that involved leveling of production, or heijunka, as it is called at Toyota. Leveling aims at organizing production at constant and predictable rates, thus eliminating the need for weekly/daily production planning, replanning and steering, and enabling flow. The idea is to produce the biggest products in the same sequence, at the same time, every week. These products are called “green” products. Not only is such an approach more “efficient” than endless planning and steering (and does away with most of it), it also allows workers and engineers to work in predictable, steady rhythms. Which in turn dramatically increases opportunities for learning and improvement. All of this makes Lean RFS more than a mere “lean tool”, but a truly transformational approach to mass production companies.

How to combine Lean RFS with Beta and other time-based approaches

Lean RFS is an ingenious, highly effective and “open source” approach to lean-that-deserves-the-name. A basic Lean RFS setup can be put into practice within days or weeks – especially because is a consistently systemic way of getting to flow. Ian Glenday, the creator of Lean RFS, was awarded the Shingo Award for his work on the approach twice, in 2010 and 2013.

What I find especially attractive about Lean RFS is that this approach is 100% in line with BetaCodex principles, and can thus be easily be combined with Cell Structure Design. Lean RFS can also be combined with the other two great time-based lean approaches: The Weichselbaum system (developed by Ernst Weichselbaum) and Quick Response Manufacturing (QRM) (developed by Rajan Suri).

At Bayer Bitterfeld, for example, Cell Structure Design and Lean RFS have been combined on a relatively large scale, which enabled the site to bring Bayer’s Dynamic Shared Ownership (DSO) principles to life. The decentralized cell structure that went live in January 2025 will allow Bayer Bitterfeld to go through several waves of improvement, with shorter and shorter production cycles, executed by ever more autonomous, self-steering and business-oriented teams.

Getting to lean in process industries and Fast-Moving Consumer Goods

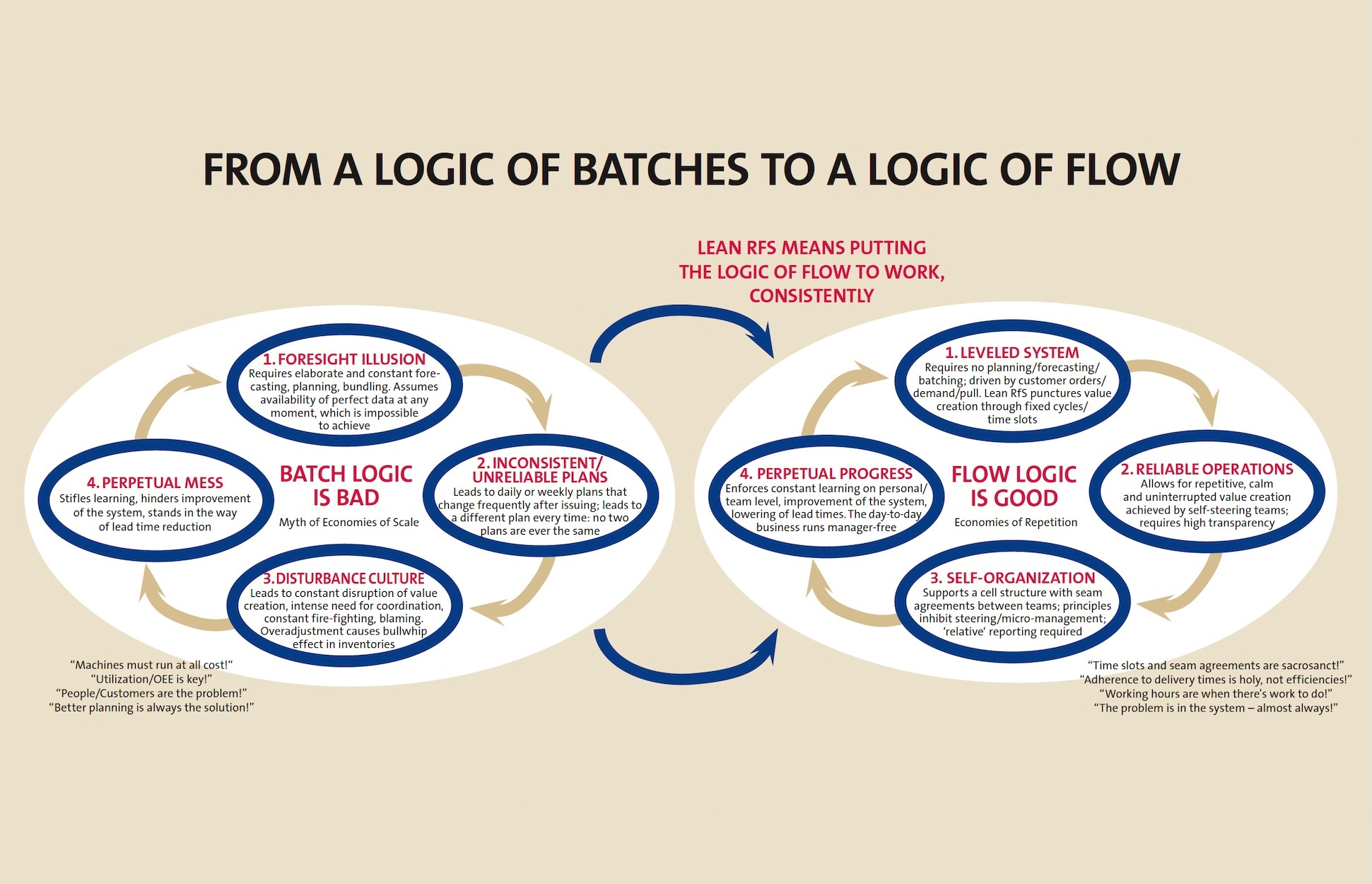

Now, for the first time, a one-page visualization of the key Lean RFS ideas is available: We produced an attractive A1 concept overview poster that's you can use for your personal learning, in workshops, for lean work and transformation/improvement project, and which you can pin on the wall to promote the approach.

The poster's content is primarily based on the excellent book Lean RFS (Repetitive Flexible Supply): Putting the Pieces Together by Ian Glenday and Rick Sather. But the poster also includes aspects of Cell Structure Design and from Ernst Weichselbaum's work.

Even Lean RFS creator Ian Glenday was impressed when he saw the poster’s design for the first time. Ian says about the poster: "It's the whole Lean RFS book on one page: That's impressive. I particularly liked the combination of the principles and the benefits these give." The concept overview poster is available from the Red42 web shop, exclusively. You can order the poster here – it is available in two languages: English and German.

About the Lean RFS concept overview poster

Direct link to the product. Color printing, A1 format folded to A4 format.

Just EUR 9.00 per copy. Volume discounts are available, as is international shipping.

Great article - thanks Ian Glenday.